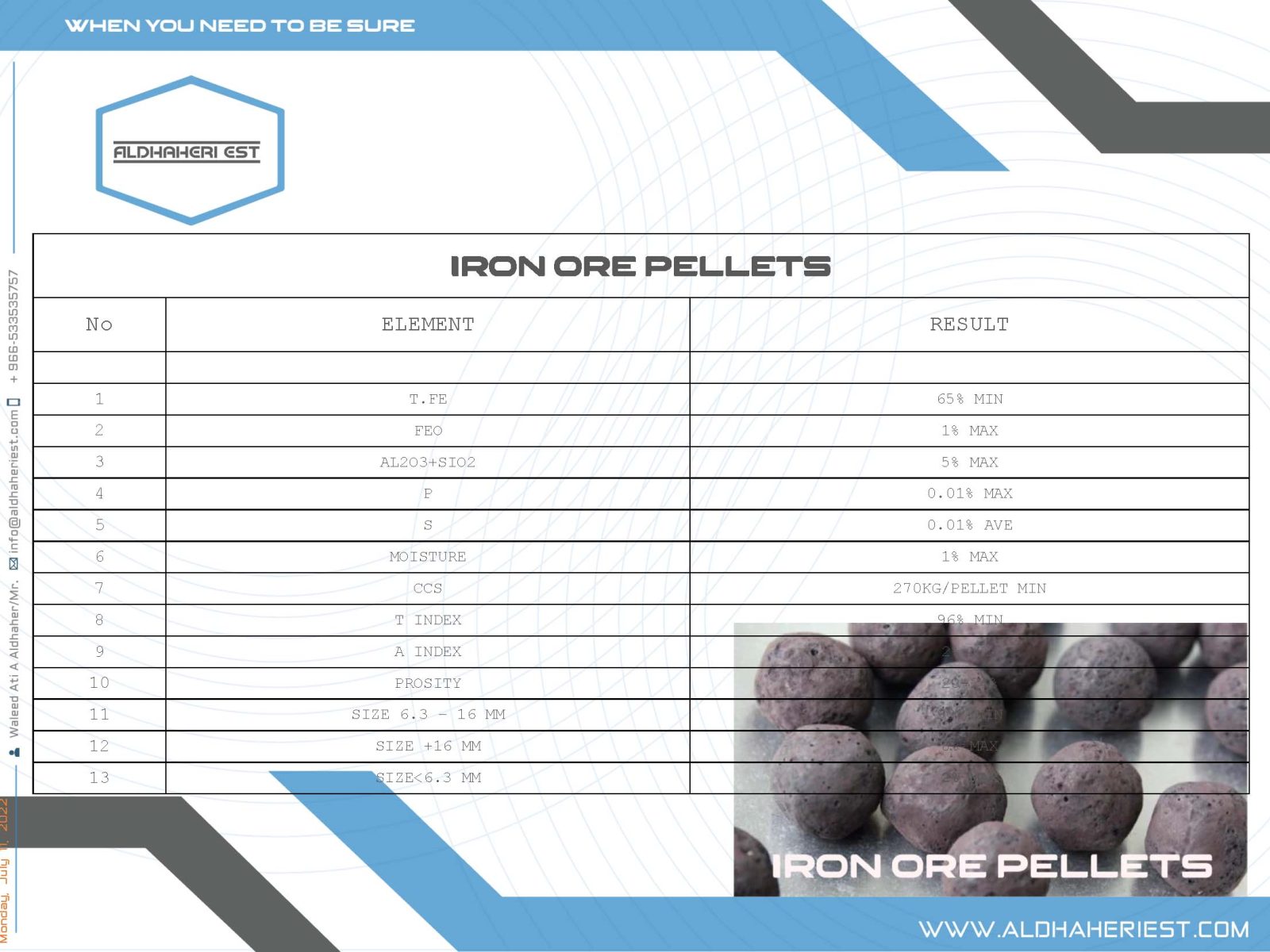

IRON ORE PELLET

DIRECT REDUCED IRON (DRI), ALSO CALLED SPONGE IRON,[1] IS PRODUCED FROM THE DIRECT REDUCTION OF IRON ORE (IN THE FORM OF LUMPS, PELLETS, OR FINES) INTO IRON BY A REDUCING GAS PELLETIZING IS THE PROCESS OF COMPRESSING OR MOLDING A MATERIAL INTO THE SHAPE OF A PELLET.

A WIDE RANGE OF DIFFERENT MATERIALS ARE PELLETIZED INCLUDING CHEMICALS, IRON ORE, ANIMAL COMPOUND FEED, PLASTICS, WASTE MATERIALS, AND MORE.

THE PROCESS IS CONSIDERED AN EXCELLENT OPTION FOR THE STORAGE AND TRANSPORT OF SAID MATERIALS.[1] THE TECHNOLOGY IS WIDELY USED IN THE POWDER METALLURGY ENGINEERING AND MEDICINE INDUSTRIES.[2]

PELLETIZING IRON ORE IS UNDERTAKEN DUE TO THE EXCELLENT PHYSICAL AND METALLURGICAL PROPERTIES OF IRON ORE PELLETS.[1] IRON ORE PELLETS ARE SPHERES OF TYPICALLY 6–16 MM (0.24–0.63 IN) TO BE USED AS RAW MATERIAL FOR BLAST FURNACES. THEY TYPICALLY CONTAIN 64–72% FE AND VARIOUS ADDITIONAL MATERIAL ADJUSTING THE CHEMICAL COMPOSITION AND THE METALLURGIC PROPERTIES OF THE PELLETS.

[3] TYPICALLY LIMESTONE, DOLOMITE AND OLIVINE IS ADDED AND BENTONITE IS USED AS BINDER.

IRON ORE PELLET SPECIFICATION