PIG IRON, CRUDE IRON

PIG IRON, ALSO KNOWN AS CRUDE IRON, IS AN INTERMEDIATE PRODUCT OF THE IRON INDUSTRY IN THE PRODUCTION OF STEEL WHICH IS OBTAINED BY SMELTING IRON ORE IN A BLAST FURNACE. PIG IRON HAS A VERY HIGH CARBON CONTENT, TYPICALLY 3.8–4.7%,[1] ALONG WITH SILICA AND OTHER CONSTITUENTS OF DROSS, WHICH MAKES IT VERY BRITTLE AND NOT USEFUL DIRECTLY AS A MATERIAL EXCEPT FOR LIMITED APPLICATIONS.[2]

THE TRADITIONAL SHAPE OF THE MOLDS USED FOR PIG IRON INGOTS IS A BRANCHING STRUCTURE FORMED IN SAND, WITH MANY INDIVIDUAL INGOTS AT RIGHT ANGLES[3] TO A CENTRAL CHANNEL OR “RUNNER”, RESEMBLING A LITTER OF PIGLETS BEING NURSED BY A SOW. WHEN THE METAL HAD COOLED AND HARDENED, THE SMALLER INGOTS (THE “PIGS”) WERE SIMPLY BROKEN FROM THE RUNNER (THE “SOW”), HENCE THE NAME “PIG IRON”.[4] AS PIG IRON IS INTENDED FOR REMELTING, THE UNEVEN SIZE OF THE INGOTS AND THE INCLUSION OF SMALL AMOUNTS OF SAND CAUSE ONLY INSIGNIFICANT PROBLEMS CONSIDERING THE EASE OF CASTING AND HANDLING THEM.

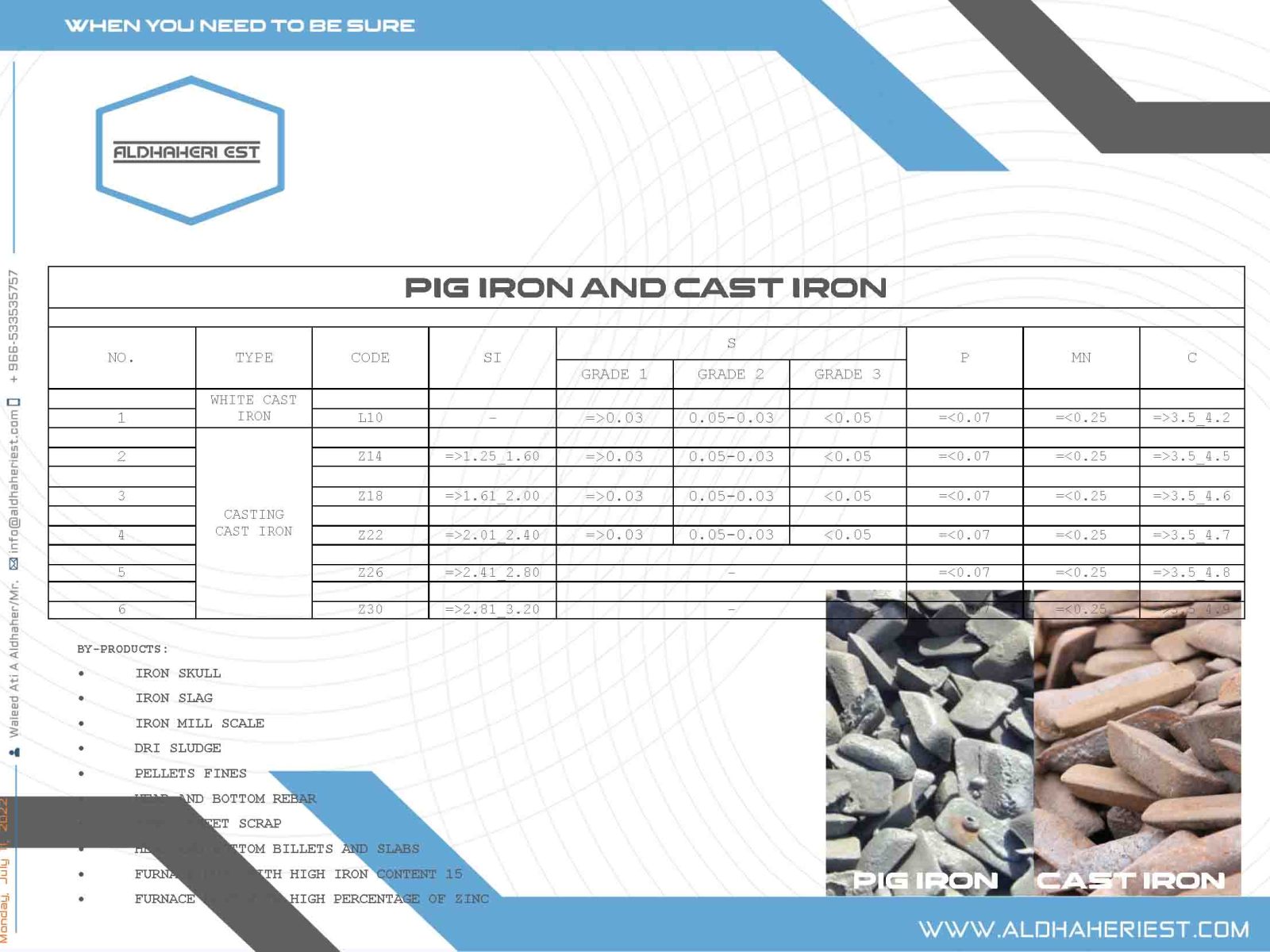

PIG IRON SPECIFICATION